As part of Digital Drive’s first birthday celebrations on 30th January 2019, we’re profiling some of the businesses involved in the programme so far...

Company Name

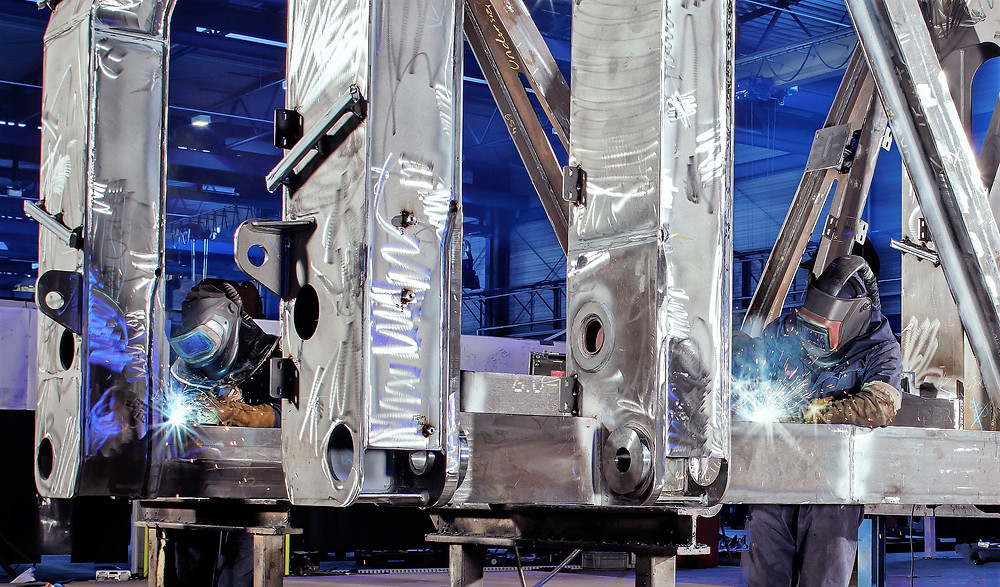

Dyer Engineering

Your Name

Richard Larder

What does your business do?

Dyer Engineering specialises in the machining and fabrication of complex metalwork and components for the rail, marine, power, automotive and offshore sectors.

The Company’s three distinct divisions offer a full suite of services, from initial design to product manufacture. BatchLine manufactures high-integrity metal components for the automotive and rail sectors; TechProjects fabricates complex, larger structures, from design concept to production for the oil and gas and renewable energy sectors. JobShop provides repair and maintenance engineering services to support clients with their in-house manufacturing and process operations.

What’s your biggest success/ achievement of the past year?

Securing £1.95m of capital investment & being selected as a demonstrator site to take part in a national, industry-first project to prove the potential of networks technologies within manufacturing. The project will also see them benefit from a share of £230k funding, through Digital Catapult.

What’s been the best part of the Digital Drive programme for you so far?

Funding support to help launch our Intranet and app development to migrate paper-based processes into digital workflows. The new cloud-based architecture will not only future proof the business, it will leverage operational efficiencies and turn masses of data into insightful information, which can be shared to all levels of the organisation, in real time and accessible through mobile technology.

What’s the best tip you’ve picked up from attending Digital Drive workshops that you’d like to pass on to others?

Digital Catapult North East Tees Valley (NETV) Digital Manufacturing Programme, a regional initiative designed to help manufacturers of all sizes understand the impact of advanced digital technologies and how to use them to future-proof their businesses.

What’s next for your business over the coming year?

- Delivering a business plan which will create an additional 100 jobs and grow the company from a turnover of £13m to £22m by 2022.

- Deployment of LPWAN (low powered WAN) technology for asset tracking of our WIP in real time and being a demonstrator site to showcase this technology.

- Machine monitoring deployment and OEE analysis

- ERP Software Upgrade

- Further development and deployment of our Intranet through app design, digital workflows and surfaced insights through MS Business Information

- Gamification of the shop floor